R&D and Quality Control

We rely on constant R&D for developing or innovating new formulations or products. Our R&D department plays an integral role in the life cycle of a product. In line with our philosophy of being an environmentally conscious and responsible business, our R&D team focuses on creating efficient, sustainable, and eco-friendly products. While, generally, our efforts to customized products are driven by customer requirements, we do also innovate and develop products. We embark upon attempting innovations only after our internal team undertakes a market survey and products are developed based on extensive feedback from our customers and other relevant industry participants.

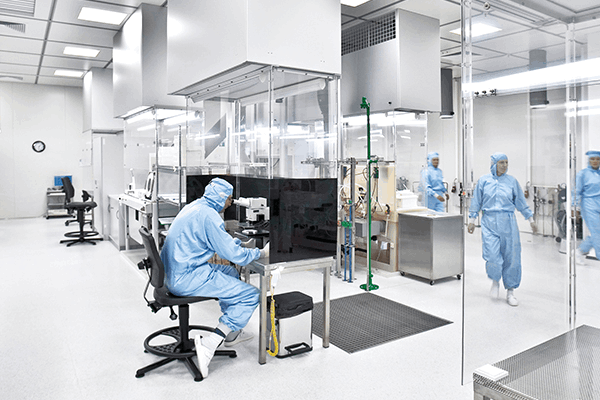

With a view to augment our focus on R&D we have developed a dedicated in-house R&D facility located at our Manufacturing Facility in Vapi. Our laboratory is equipped with modern equipment and instrumentation which enables us to undertake pharmaceutical gas chromatography and high performance liquid chromatograph. We are also equipped to conduct various chemistries/ technologies. Our R&D facilities are equipped with inter alia with ‘gas chromatography-mass spectrometer’ (GC-Mass Spec) and ultra-violet spectrometer, etc. We also have a highly qualified and experienced team that is dedicated to R&D. The team comprises of 19 employees with doctorates and post-graduation degrees.

We believe that maintaining high standard of quality in our R&D and manufacturing operations is critical to our growth and success. We have implemented quality systems across our Manufacturing Facilities that cover the full product lifecycle. All our products from being a raw material to the finished product undergoes 6-8 checks depending on process flow. Raw materials received are sent for the quality analysis, the technical department is responsible for carrying out this procedure. Various samples are drawn by technical person and requisite tests are carried out for specified properties as per the standard procedures, on satisfactory outcome, material is allowed to be stored in the designated area for further processing.